Barn

Barn - permanent surface protection for e.g. tack room and feed room

1595,00 SEK

5 liters x 2

Surface protection that provides a dust-free and more easily cleaned floor.

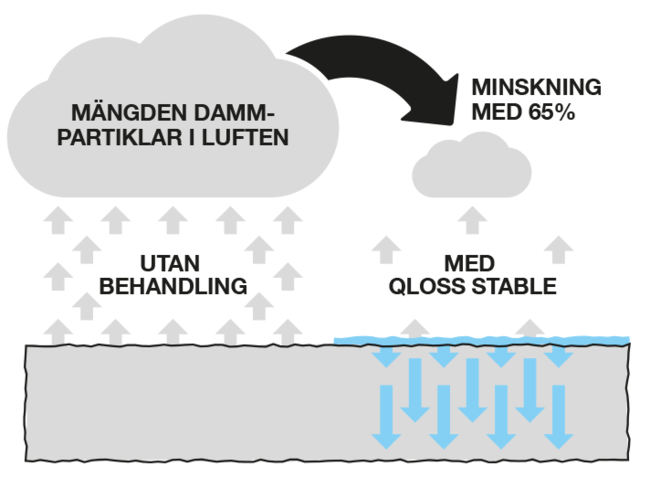

Barn is a surface protection product for floors made of concrete, screed, brick, or cement. In many stables and machine sheds, the floors are often untreated. An untreated concrete or screed floor, for example, is porous, which means it releases dust through any contact with it. By applying Barn, you get a dust-free floor that is easier to clean.

Barn consists of two components and is the perfect surface protection product for your tack room, feed room, machine shed, hay room, etc. The product protects floors by forming a membrane coating on the surface, thereby strengthening and protecting your floor from wear and tear. Barn penetrates deeply into the substrate, and the membrane coating makes the floor completely dustproof, stain repellent, and much easier to keep clean. The product is easy to apply and, of course, environmentally friendly.

Barn should not be applied to surfaces on which horses with shoes walk. The surface protection product can make it slippery for horses with steel shoes.

Examples where Barn can be applied:

- Tack rooms, feed rooms and machine sheds

- Cafeteria

- Washing and drying room

- Existing, freshly sanded or newly laid flooring of mineral substrate, such as concrete, floating putty and brick.

- The product should not be applied to surfaces where horses with shoes walk on the floor. The surface protection may make it slippery for horses with iron shoes.

The products are easy to apply. The idea is to finish the treatment in a couple of hours. The floor needs to be at a minimum temperature of 10°C during application.

1. Clean the substrate by sweeping, flushing or vacuuming. Surfaces to be coated shall be clean and dry at the time of application.

2. Part 1: Use a pressure sprayer and spray the product over the floor, then spread the product evenly with a short-haired cleaning tool (micro-mop or similar), or a soft broom. Drying time approximately 1-4 hours depending on temperature and ventilation in the stable.

3. Part 2: Once Part 1 has dried, apply Part 2 as above.

Material consumption: 5 liters of part 1 and part 2 is enough for about 100m².

Part 1: Aqua, Styrene-acrylic polymer, Aminomethyl propanol, Dithiomethylbenzamide, 2-bromo-2-nitropropane-1,3-diol.

Part 2: Aqua, Polyurethane, Acrylate, 1-(2-butoxy-1-methylethoxy)propan-2-ol, PPG-2 methyl ether, Wax, Defoamer, Triethylamine, Wetting agent, Thickener, Ammonium hydroxide, Methylisothiazolinone, Benzisothiazolinone, Reaction mass of 5-chloro-2-methyl-2H-isothiazol-3-one and 2-methyl-2H-isothiazol-3-one (3:1)